Commissioning tests for data centers

Rentaload offers for commissioning tests on datacentres the rental of SMART and connected load banks . This equipment makes it possible to test all levels of electrical and thermal redundancy of infrastructures, from the end of construction, renovation or during maintenance operations:

- Test of the main electric chain;

- Emergency electrical chain test and emergency equipment test;

- Test of the room cooling system.

Rentaload also offers a full range of associated services (delivery, installation and connection, test assistance).

Today, Rentaload’s expertise in this type of test is known and recognized worldwide.

What to know about commissioning tests for data centres

- What is a commissioning test?

These are types of tests specific to the “data centre” sector. We come to test all the levels of electrical and thermal redundancy of the infrastructure (main track / track and emergency equipment: generators, batteries, inverters) individually but also co-ordinated. The objective is to guarantee the quality and reliability of the data centre.

According to the American Society for Heating , Refrigerating and Air Conditioning Engineers (ASHRAE ), commissioning is the “quality-focused process of realising, evaluating, and documenting that the performance of buildings, systems, and assemblies meet defined objectives and criteria”.

In other words, it consists of verifying and validating that the design and construction comply with the requirements and specifications of the initial project.

This is a very specific process with applicable standards: ASHRAE Testing Standards.

“Done correctly, commissioning improves system performance throughout the lifecycle of a data centre. Better system performance not only optimises the performance of the data centre, but also lower O&M costs and lower energy consumption for lower electricity bills.” – Michael Donato, Data Center Knowledge

-

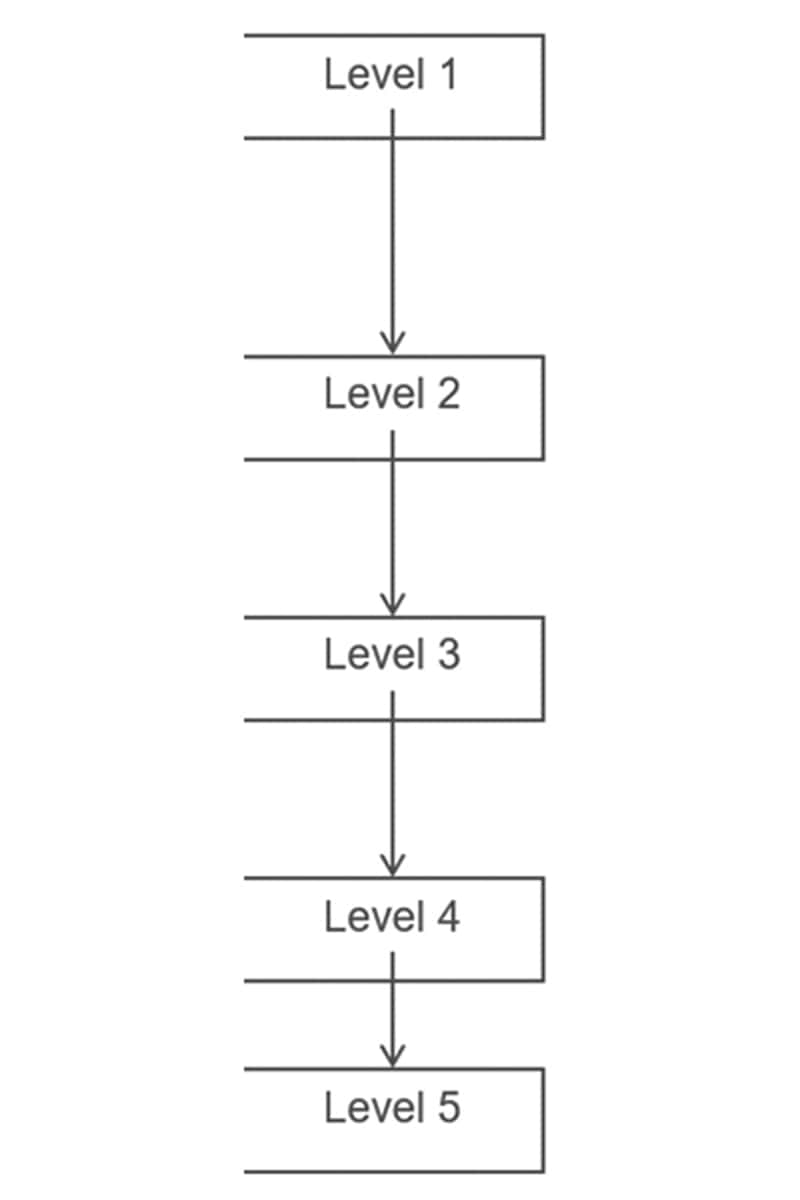

The different levels of commissioning

This is a continuous process that ideally starts in the preliminary project phase and extends into the operating phase of the IT rooms.

Level 1: Factory Test or Factory Acceptance Test (FAT)

The factory acceptance tests or FAT take place at the manufacturer of the machine (in the factory), they make it possible to check the proper functioning of the machine in accordance with the specifications specified beforehand in the specifications. It is therefore an extremely important step. One of the main uses of the FAT test is to avoid shipping a defective or malfunctioning machine to the customer.

Following the FAT test, a report summarising the various checks must be drawn up.

Level 2: Inspection or on-site acceptance test (SAT)

Once the equipment is delivered to site, it is inspected by the commissioning agent (verification control). This is to ensure that the equipment is what was ordered and also meets the project requirements. These checks are usually recorded via check sheets and are part of the overall process.

Level 3: Pre-functional testing (EPF) or component functional testing (EFC)

This is the installation inspection of the equipment only. The builder and commissioning agent work together to determine if the equipment has been installed correctly and meets industry requirements and regulations. It is also the first time that the equipment has been put into operation and its operation has been checked.

Level 4: Functional Performance Test (FT) or Functional System Test (FST)

Once Level 3 inspections and start-up testing are complete, the process moves to Level 4, functional performance and site testing. These are additional tests to verify that the equipment is working as expected and that faults have been properly incorporated.

Level 5: Integrated Systems Testing (IST)

These are the final tests. During this final stage, the focus is on proving that all systems can work together and meet the expected design and project requirements. Tests typically return mechanical systems, known as “thermal load testing”, and electrical systems, known as “integrated electrical testing”. They are usually run separately as they have slightly different goals.

Thermal load tests are performed to prove that the thermal response of the computer room under different heating load conditions and failure scenarios are within the tolerances stipulated by the design.

Built-in electrical tests are performed to prove that in the event of certain failures in electrical systems and incoming power supplies, data centre utilisation will not be affected and will maintain its operating condition without downtime.

These tests are performed with a minimum of repeats. If any of the level 5 tests do not yield the expected results, the cause of the anomaly is identified and corrected and the test is then repeated. This is a very important step because if it fails, the data centre will not be approved and the customer will generally not be able to use or rent the space.

-

Our field of expertise

Our field of expertise

Rentaload most commonly assists with level 3, 4 and 5 commissioning tests .

We come to check with the help of our commissioning agent and our dedicated equipment that everything is working perfectly inside the datacentre (whether electrical or thermal equipment, individually or coordinated).

In connection with the deployment of our equipment on site, our teams support with varying levels of commitment the different phases of the commissioning tests. Acting as a simple assistant to on-site commissioning teams, we can also take charge of a commissioning project from A to Z.

We therefore take care of:

- Writing the test protocol upstream;

- Carrying out on-site tests;

- Recording and processing of data;

- Preparation of the final test report.

We have always been driven by the vision that commissioning can be done differently. We believe that this phase can be optimised, in particular thanks to our SMART equipment and solutions: connected load banks and supervision software (Rentalab and EkkoSense). Amongst other things, this allows Commissioning teams to:

- Save time in carrying out their tests (up to 20%) thanks to the remote control of load banks via a supervision PC;

- To bring added value to the tests, in particular thanks to the data collected (P/U/I/Delta T) via the supervision software.

Our state-of-the-art equipment perfectly meets the needs and requirements of end customers. With their low Delta T, their integrated ATS, their 50/50 load sharing and their extremely precise feedback of measurements, we are perfectly able to optimize the “test and commissioning” phase.

The customer benefits of entrusting their commissioning to Rentaload

- A guarantee to carry out the tests on time and to avoid possible late penalties;

- Long -term optimisation of commissioning thanks to dedicated equipment perfectly adapted to the configuration of the site to be tested (intelligent equipment acting as real server simulators) with a time saving of 20% according to our customers;

- Added value brought to the tests thanks in particular to the data collected through our connected load banks and our supervision software;

- A commissioning strategy worked upstream with the client in order to optimise the tests on D-Day.

Which loadbanks can be used for commissioning tests?

Our commissioning resources

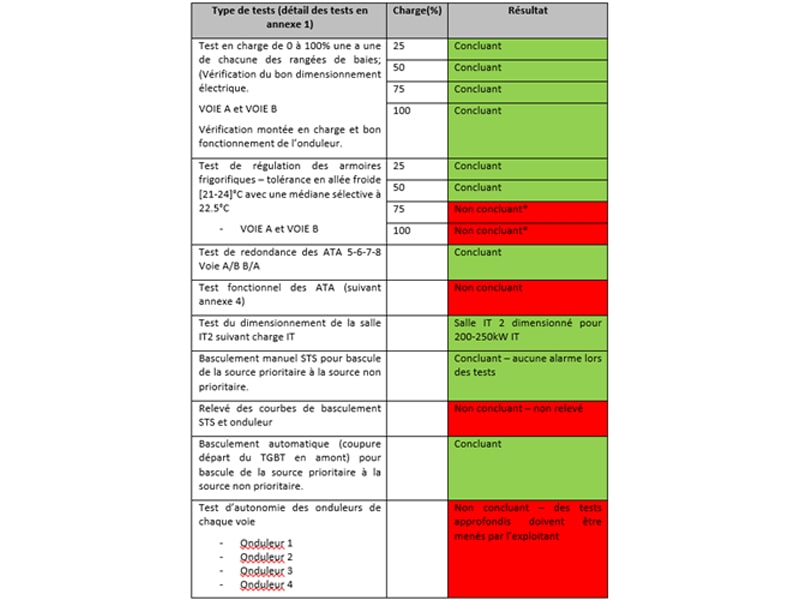

- CASE STUDY

Project characteristics

✔400KW

✔Extension of a computer room in an existing campus.

✔The other rooms remain in service

Achieved scope

✔Room modeling

✔Level 5 commissioning program (commissioning)

✔Implementation of “Test and Commissioning” procedures (risk management and mitigation)

✔Manage the “Test and Commissioning” process

✔Establish the final report

Commissioning tests carried out made it possible to highlight a problem on the existing electrical system (in production): a bench battery, replaced 3 months previously, was out of service. This test made it possible to replace the battery and avoid a power failure on the UPS network.

2. CUSTOMER TESTIMONIALS

Works project manager – DALKIA (Feb. 2021)

“We called on Rentaload for the “Test & Commissioning” part of our datacenter. The tests went very well and what we particularly appreciated were the exchanges with the team on site as well as their professionalism! commissioning allowed us to check the Datacenter tunnel and its proper functioning. A final report listing all the electrical & thermal data was then provided to us, allowing us to confirm the proper functioning of the tunnel with the few adjustment points to be provided by the suite. This service is for us a real guarantee of the proper functioning of our infrastructure, its compliance and it is also a subsequent means of improving the performance of our datacenter. We highly recommend it.”

Business Manager – Bouygues Energies and Services (April 2021)

“We had to carry out level 4 and 5 (*) tests for a large data center in Paris. We therefore went through Rentaload in order to benefit from a turnkey service: rental of load banks and accessories (shelves, shutters, cables and measurement accessories) to carry out the tests, delivery, installation and complete commissioning service (**).We had rented from them sixty of their 7 KW SMART rack load banks; which moreover act as real server emulators. We were pleased with this equipment. They are indeed very good products. However, there were a few failures during testing and we would have liked to have had a Rentaload technician on site at the time to help us with fix these few malfunctions. We will know for next time. We were also satisfied with the Commissioning service. The 2 Rentaload experts who came to carry out the tests were really competent and extremely responsive to requests from the client and the design office. A whole host of details could also be settled on site, which we greatly appreciated (= time saving)! The final test report took a little longer to arrive, but the client was still very happy with the service.”

- Also download for free our commissioning guide (2020) produced in partnership with the DDA (Dutch Data Center Association) and several players in the data center industry in the Netherlands

- Discover our web mini-series on our YouTube channel : “Deerns – Rentaload for successful commissisoning!” »