Why Our DLC testing Services?

Risk Mitigation

Safe, repeatable processes to help prevent leaks, corrosion, and contamination in DLC load banking equipment. Therefore, it helps keep critical systems in service.

Reliable Performance

Controlled cleaning and preparation of all loadbanking equipment to reduce issues and support consistent thermal performance.

Sustainability

Reduce waste where possible via reuse/recycling options, with compliant handling and disposal.

Full-Lifecycle Partner

Support from pre-commissioning through routine maintenance and rapid intervention when needed.

Looking to test & commission DLC equipment?

See our DLC Testing Equipment Range »

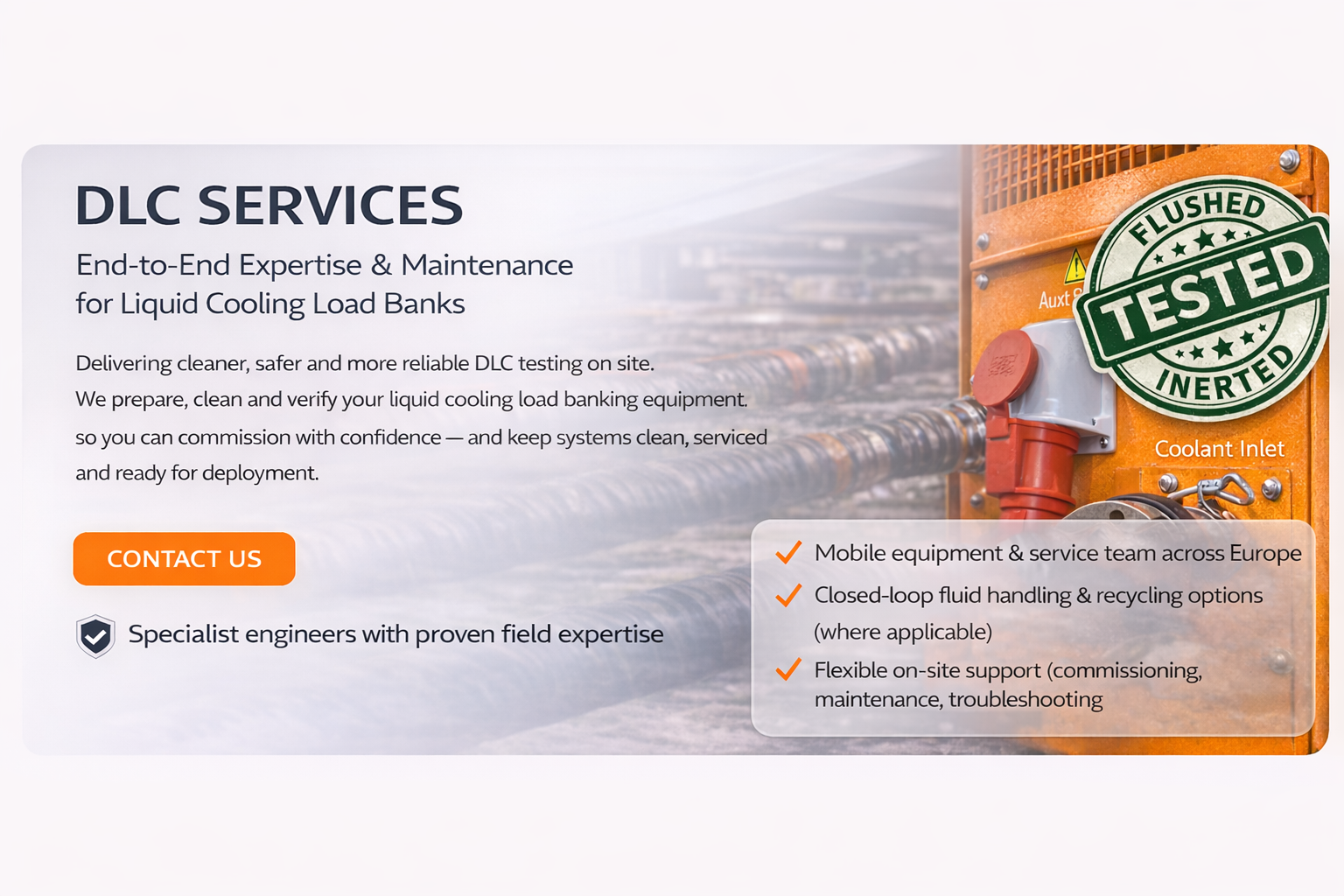

Our Proven Process

Draining

Flushing & filtering

Testing

Drying

Inerting

Assuring DLC loadbank readiness with safe, repeatable steps:

Draining — Liquid removal + safe storage/handling

Flushing and filtering — Clean circuits + remove debris/residues

Testing — Check pressure levels + leak detection

Drying — Moisture elimination + contamination prevention

Inerting — Prepare/protect the circuit for next commissioning